Digital measuring systems, leveraging technologies like 3D scanning, computer vision, and optical sensors, have revolutionized industries by providing accurate, efficient data collection methods. In auto repair, these systems enable non-destructive assessments, precise mapping of damages, and exact alignment during reconstruction, enhancing quality control and reducing human error. Beyond automotive, digital measuring systems streamline workflows, drive innovation, and ensure meticulous geometry capture in manufacturing, construction, and medicine, making them indispensable tools for modern industries striving for excellence.

Digital measuring systems have transformed how we quantify and analyze our world, offering unprecedented accuracy and efficiency. This article serves as your comprehensive guide to understanding these cutting-edge technologies. From the basics of how they work to exploring diverse types and their wide-ranging applications, you’ll gain valuable insights into digital measurement’s impact across industries. Discover how these systems enhance productivity, improve precision, and drive innovation in today’s tech-driven landscape.

- Understanding Digital Measuring Systems: The Basics

- Types of Digital Measurement Technologies

- Applications and Benefits in Various Industries

Understanding Digital Measuring Systems: The Basics

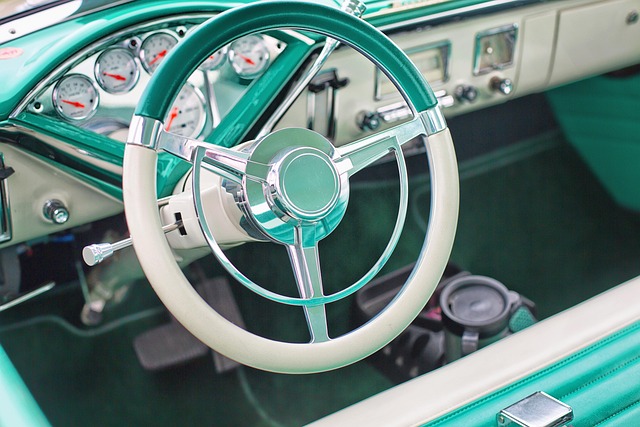

Digital measuring systems have revolutionized various industries, including automotive sectors like car collision repair and auto body repair. These advanced technologies offer precise and efficient methods for gauging dimensions, ensuring accuracy in manufacturing, assembly, and after-sales services. At their core, digital measuring systems utilize sensors and software to capture, process, and interpret data from physical objects or surfaces.

The basics involve a device scanning or contacting an object to gather measurements. This information is then translated into digital formats, such as 2D or 3D models, allowing for detailed analysis and comparison. In the context of car body repair, these systems can non-destructively assess damage, map out repairs required, and ensure precise alignment during replacement or reconstruction processes.

Types of Digital Measurement Technologies

Digital measuring systems have revolutionized various industries by providing accurate and efficient data collection. These technologies come in diverse forms, each offering unique advantages for specific applications. One prominent type is 3D scanning, which utilizes laser or camera-based systems to capture detailed digital representations of physical objects. This method is widely used in manufacturing for quality control, ensuring precise dimensions and identifying defects, such as dents or imperfections, in car body shop services.

Another significant technology is computer vision, employing cameras and image processing algorithms to analyze visual data. It finds extensive use in quality inspection processes, especially in tire services, where it can detect subtle variations and ensure product consistency. Moreover, digital measuring systems also incorporate touch probes and optical sensors, providing non-contact measurements for intricate geometry capture. These technologies collectively enhance precision, streamline workflows, and drive innovation across multiple sectors.

Applications and Benefits in Various Industries

Digital measuring systems have revolutionized various industries, offering precise and efficient solutions for tasks that were once time-consuming and error-prone. These advanced technologies play a pivotal role in ensuring quality control and precision in critical processes. One of the most notable applications is in the automotive industry, particularly within car paint services and vehicle bodywork repair. With digital measuring tools, technicians can quickly assess and record the dimensions of damaged areas, enabling precise repairs and exact color matching during paint jobs.

The benefits extend beyond aesthetics; accurate measurements are crucial for structural integrity in automotive collision repair. These systems streamline workflows, reduce human error, and ultimately save time and resources. Furthermore, digital measuring technologies find applications in manufacturing, construction, and even medical fields, where precision is paramount. Their versatility and effectiveness make them indispensable tools for modern industries striving for excellence in their respective domains.

Digital measuring systems have revolutionized various industries by providing accurate, efficient, and versatile data collection. From advanced sensors to cloud-based analytics, these technologies offer unprecedented insights into processes, products, and performance. As we continue to navigate an increasingly digital world, understanding the basics, exploring diverse measurement technologies, and recognizing their far-reaching applications will empower businesses and professionals to harness the full potential of this transformative toolset.